FEATURES OF MACHINE

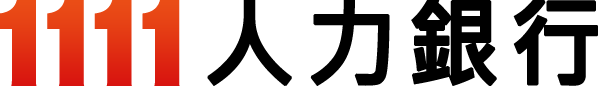

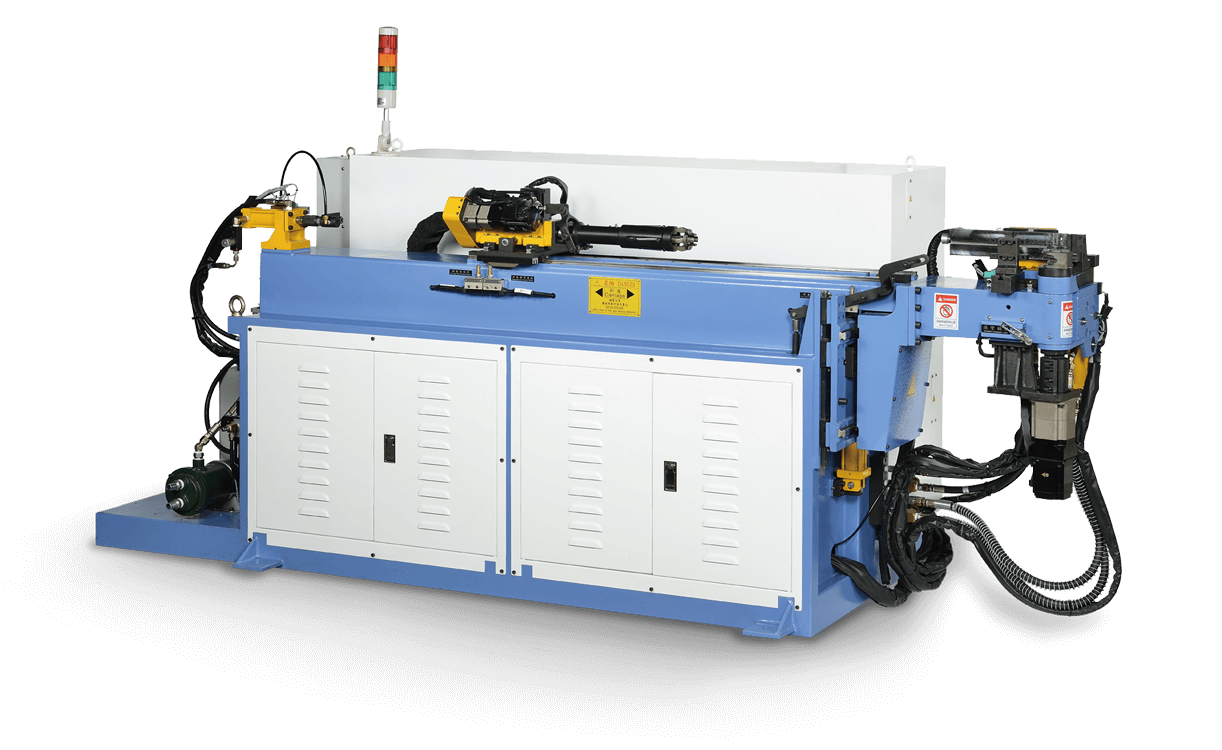

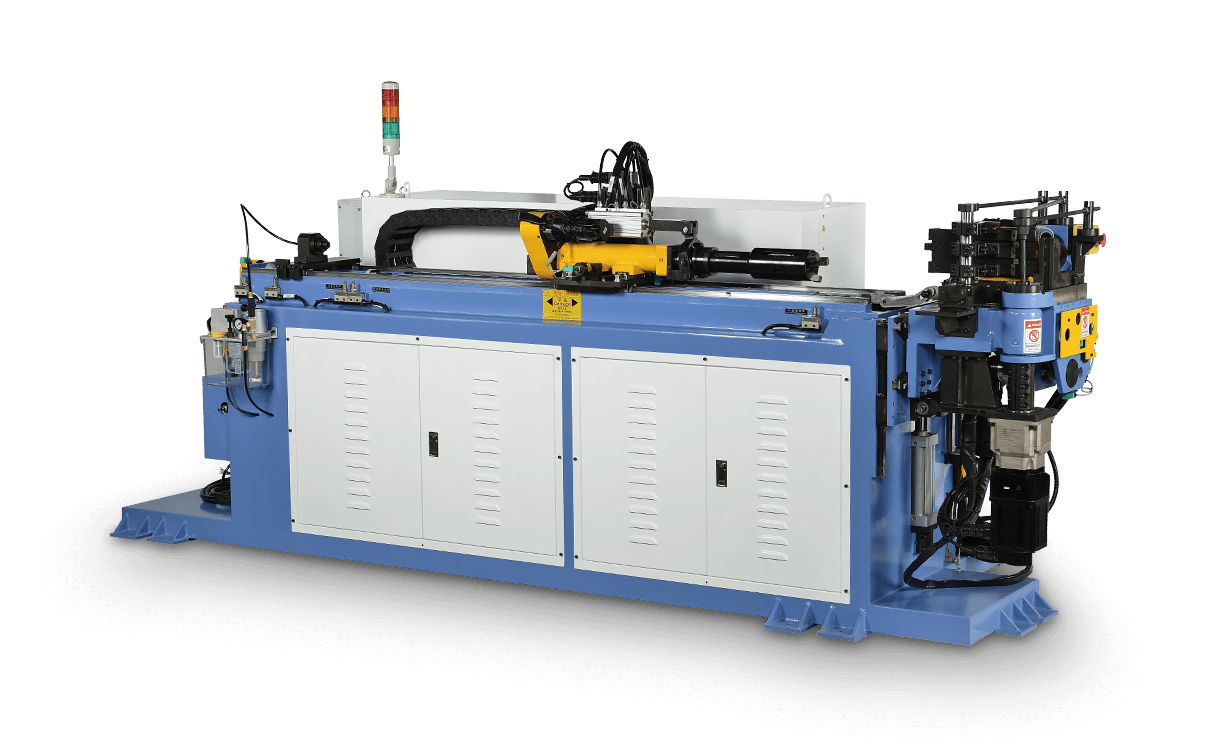

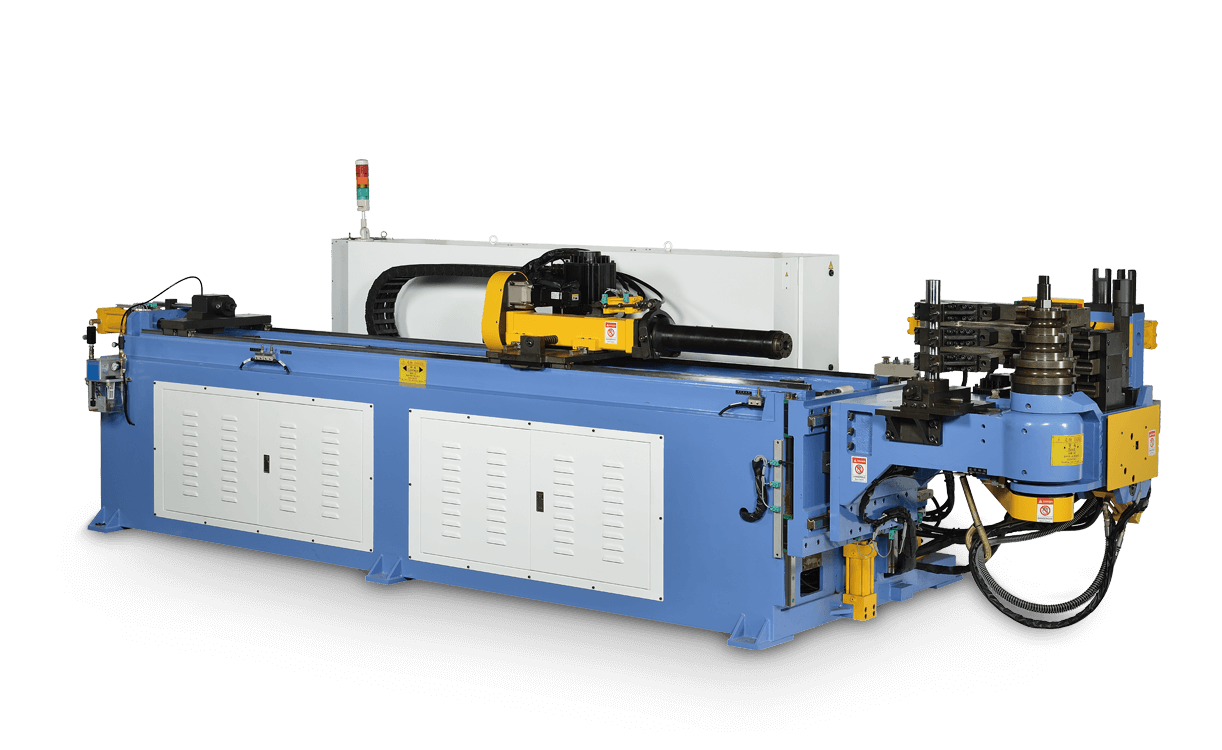

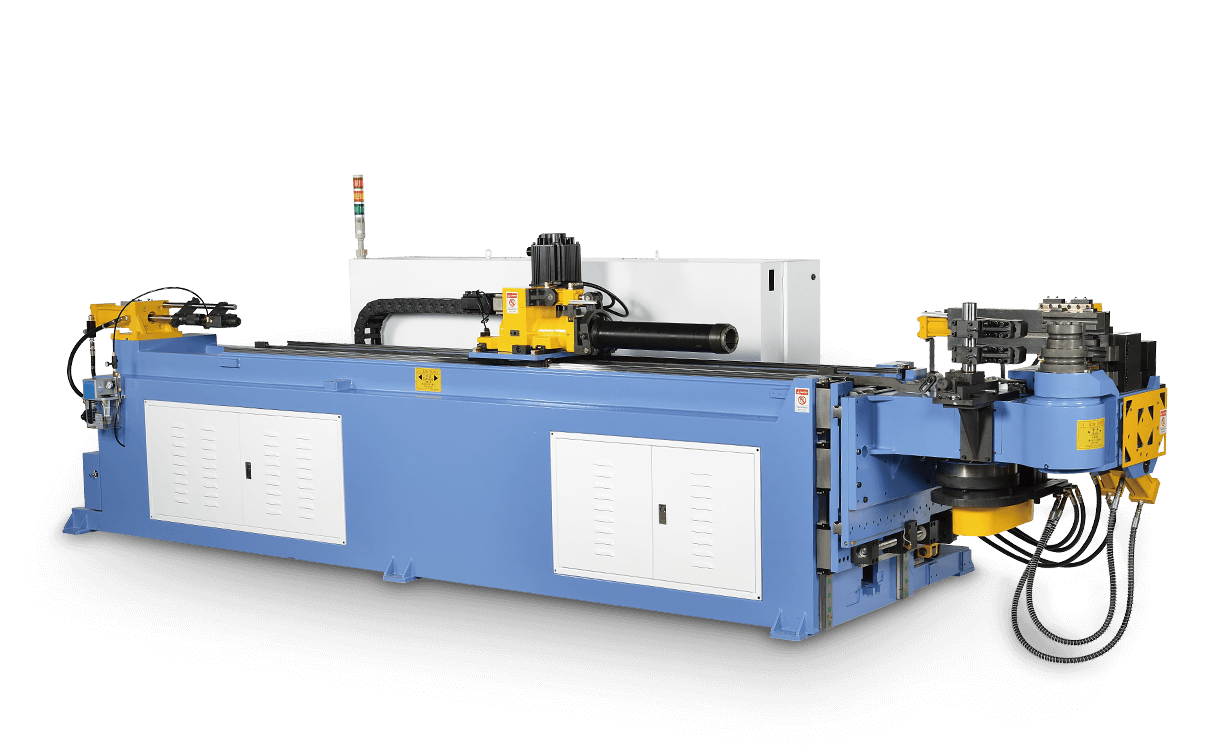

Mechanical Design

Machine's design are based on dynamic mechanical analysis to offer reliable performance.

Quick tooling changeover shortens set up time and comforts users.

Compact bend head & arm minimize the possible interferences.

High quality linear guide ways mounted on sliding mechanism ensure precise and accurate motions.

Climbing clamp design enables sufficient space to execute bending efficiently.

Individual electrical cabinet is mounted separately from the machine to prevent the affection of

3D Simulation

3D tube profile can be shown immediately when editing YBC program to help users.

3D tube preview with tooling data is shown during opening a file.

Under Auto mod, 3D tube graphic indicates current bending section by different color block.

3D Bending Process Simulation(Optional) directs bending process in advance to avoid unnecessary waste.

Optimized & Flexible Bending Setting

Operation mode: Manual, Semi-Auto, Fully-Auto, Single-Bend.

The individual motion can be set as requests during the bend cycle, such like Mandrel(on/off), 2-steps MDR retraction, boost function.

The precise movement of each axis can be executed by setting absolute / relative value.

Teach / Process function, any motions can be customized to successfully return the bend-arm to initial position.

User friendly interface with 17"touch screen / icon display.

As the request, loading a tube under move-in/out status can be specified.

Positions of each axis and bending angle are numerically shown in the screen.

Repeatable feeding / Re-capture functions are availvble for feeding.

Each axis has 9 main speed with 10 fine-tune speed to satisfy various applications.

Repeatable pressure die sliding function can be customized to execute to overcome large angle bending.

Anticipated clamping motion for clamp / pressure die could be set individually to save cycle times.

Overall lendth recommendation, the system calculates the necessary length automatically when Y.B.C data has been set.

Simultaneous axis movement on Y.B.C significantly upgrades productivity.

Total, present, count-down functions are available in the workload counter.

Batch working function, 4 files can be scheduled to produce sequentially.

Automatic display of cycle time of X.Y.Z-coordinate can be converted to Y.B.C axis.

Re-organize motion procedure to avoid touch-points effectively, under move-in/out/stack-change status to execute feeding, un-bending, rotating.

Mirror Function enables usrs to get the symmetrical shape immediately.

Reverse function enables users to get the reverse shape immediately.

Comprehensive Safety Protection

Error watch dog function on program editing & abnormal operation to effectively help users to avoid artificaial mistakes.

The safety plate equipped on the bending arm can stop the operation immediately when triggered.

The machine is protected by multi-mechanisms and program means.

The buzzer could be set alarm / non-alarm modes for abnormal situations.

Front and Rear limit switches, Carriage vibration proximity switches, Fully clamping indicators.

Overload protection prevents malfunctions due to unauthorized users modification of files.

E.M.S buttons are equipped on the foot switch and control console to handle emergent situations.

PC Besed Control System

PC Based control system in Windows operating system features remarkable fuctions and flexibility instead of conventional PLC control system.

High capacity of hard disk(500GB) can store 2,000,000 programs, no insufficient capacity issue is concerned.

The high grade industrial computer with intel CPU 2.6G above or same class CPU ensure the performance and noise free.

USB ports are available on the movable console, it's convenient for users to access files.

17"touch-screen features high resolution display and easily enables users touch to go.

Built-in 4GB USB automativally backs up users' programs whenever the machine is reboot, that guarantees no loss of users' programs.

Latest high speed DDR2 memory 2GB or above.

No limit bend numbers in YBC can achieve multi-bends task easily.

Ethernet port offers immediate connection with the manufacturer for trouble-shooting and sevice (Users need to offer internect-access).