Please select your language

Language

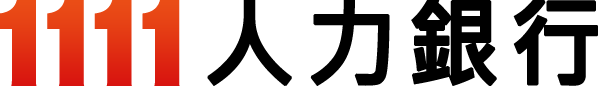

Mechanical Design

- Machine's design is based on dynamic mechanical analysis to offer reliable performance.

- Compact bend head & arm minimize the possible interferences.

- Climbing clamp design enables sufficient space to execute bending efficiently.

- Quick tooling changeover shortens set up time and comforts users.

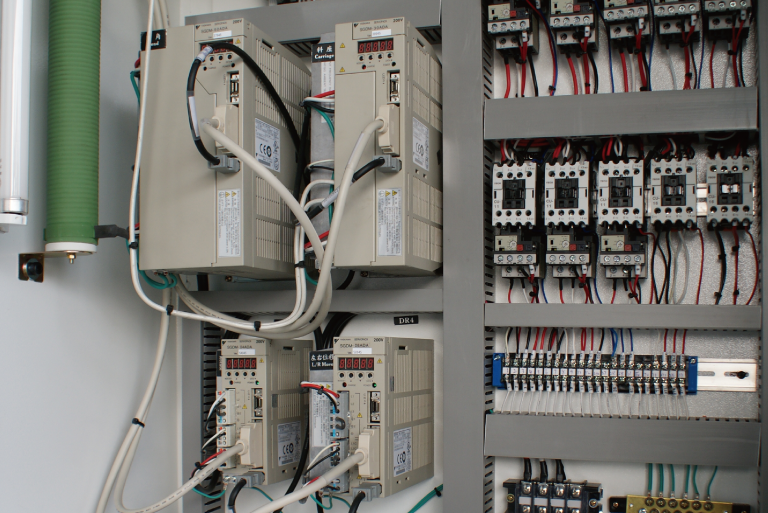

- Individual electrical cabinet is mounted separately from the machine to prevent the affection of vibration.

- Motions driven by all electric-servo motors assure the high accuracy & repetitive performance.

- Auto-Tooling Positioning Function :Clamp/Pressure die are positioned automatically via smart torque control.

- High Stability : All electric-servo control without oil temperature problem.

- Low Noise

- Low Pollution

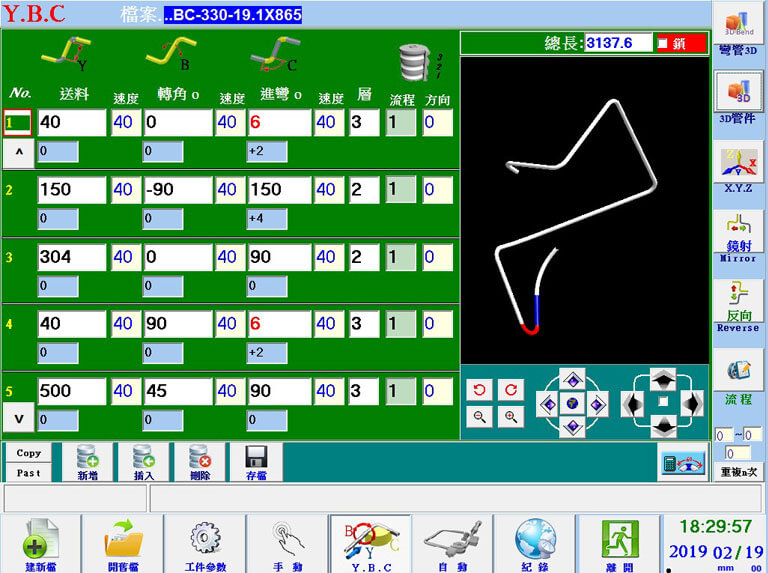

Optimized & Flexible Bending Setting

The electrical cabinet is a modular design and is separately mounted from the machine to prevent being affected by machine vibration.

The electrical cabinet is equipped with an air conditioner to keep at a constant temperature.

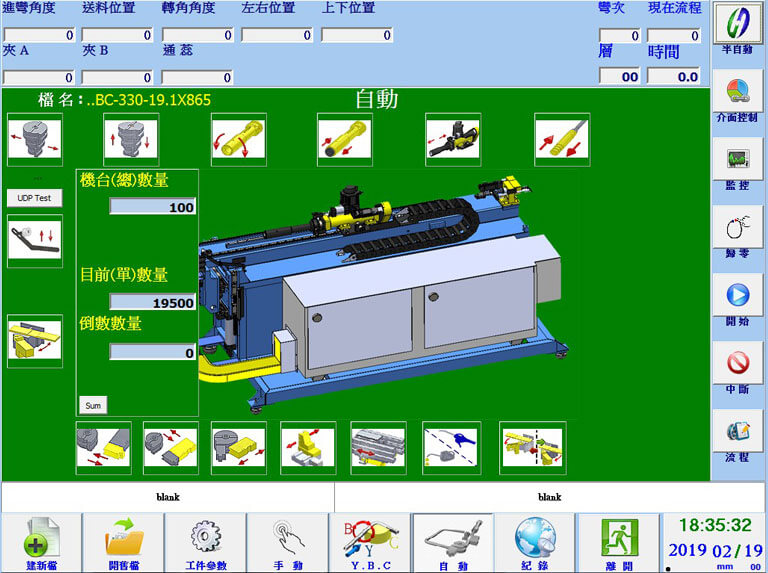

- Operation mode: Manual, Semi-Auto, Fully-Auto, Single-Bend.

- User friendly interface with 17"touch screen / icon display.

- Positions of each axis and bending angle are numerically shown in the screen.

- Each axis has 9 main speed with 10 fine-tune speed to satisfy various applications.

- The individual motion can be set as requests during the bend cycle, such like Mandrel(on/off), 2-steps MDR retraction, boost function.

- Teach / Process function, any motions can be customized to successfully return the bend-arm to initial position.

- Overall lendth recommendation, the system calculates the necessary length automatically when Y.B.C data has been set.

- Total, present, count-down functions are available in the workload counter.

- Automatic display of cycle time of X.Y.Z-coordinate can be converted to Y.B.C axis.

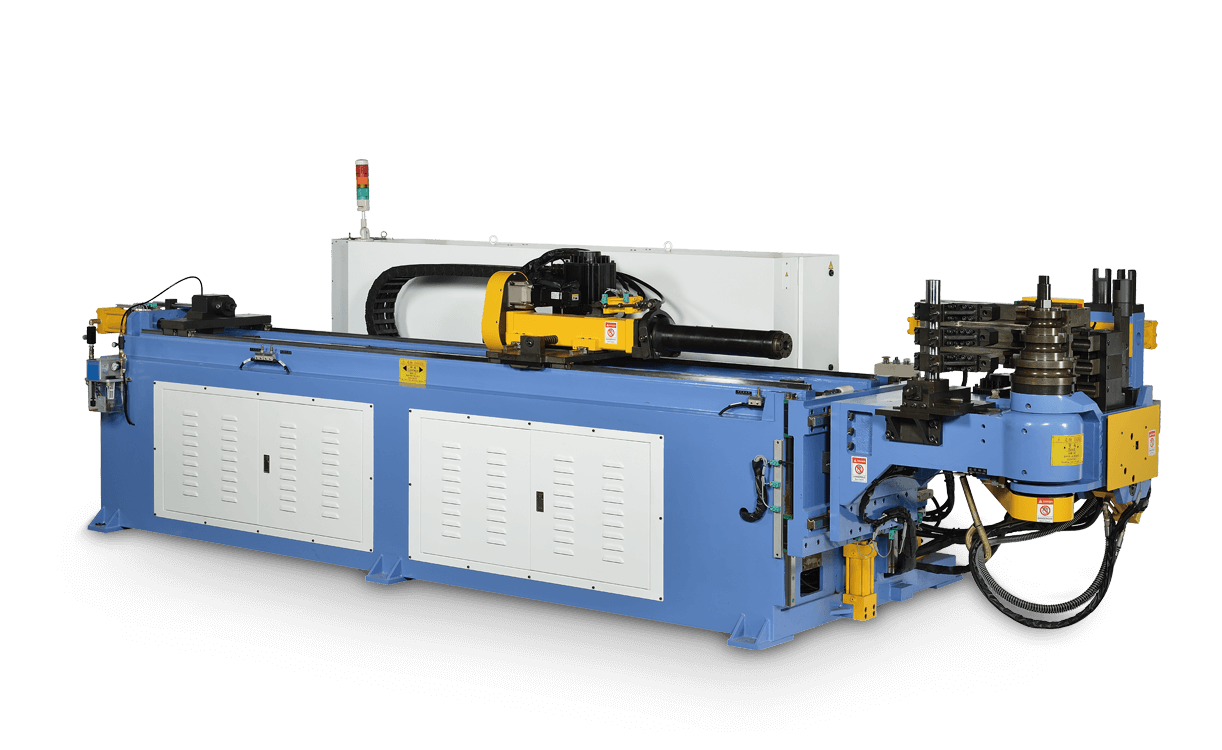

| Spec / Model | HC-500R3-NSM | |

|---|---|---|

| Max. Tube O.D. & W.T. (O.D. x t) | Mild Steel (mm) | ø50.8 x 2.5 |

| Stainless Steel (mm) | ø45.0 x 2.0 | |

| Rectangle Pipe (mm) | □45.0 x 2.0 | |

| Max. Draw Bending Radius (Max. R)(mm) | 200 | |

| Push Bending Radius | *Min. (mm) | 7D~10D |

| Max. (mm) | ∞ | |

| Max. Bending Angle (degree) | 200° | |

| Max. Effective Distance of Mandrel (mm) | 2500 mm | |

| Electric-Servo Speed | Feeding (mm/sec) | 1000 mm |

| Rotation (degree/sec) | 200° | |

| Bending (degree/sec) | 110° | |

| Electric-Servo Accuracy | Feeding (mm) | ±0.05 mm |

| Rotation (degree) | ±0.05° | |

| Bending (degree) | ±0.05° | |

| Total Power (HP) | 35.5 HP | |

| Machine Size (L x W x H)(mm) | 5100 x 1600 x 1700 mm | |

| Machine Weight (kgs) | 4,650 kgs | |

Remarks:

Read More *Min. push bending radius(mm) : it’s subject to tube O.D, W.T, tube material..etc.

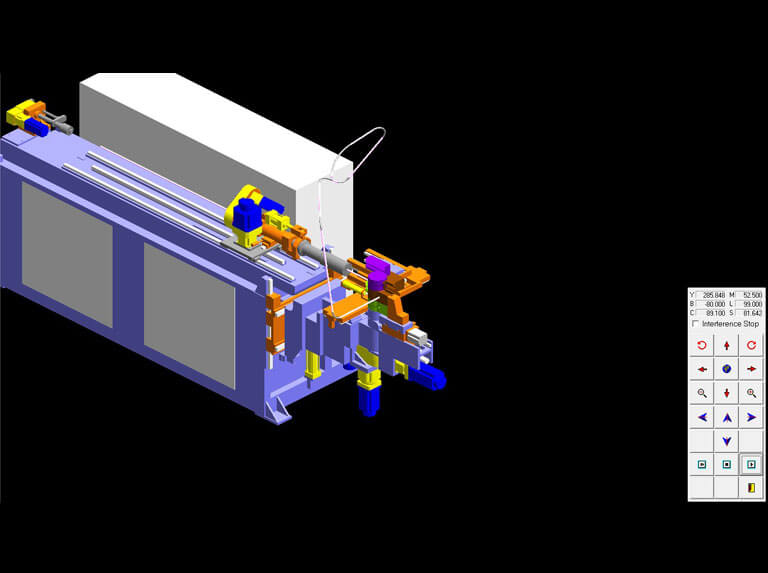

3D Bending Process Simulation (Optional)

- 3D tube profile can be shown immediately when editing YBC program to help users.

- Under Auto mod, 3D tube graphic indicates current bending section by different color block.

- 3D Bending Process Simulation(Optional) directs bending process in advance to avoid unnecessary waste.

3D Bending Process Simulation (Optional)

3D Tube Simulation

Y.B.C-axis Page

Parameter Setting Page

Manual Mode

Fully Auto. Mode

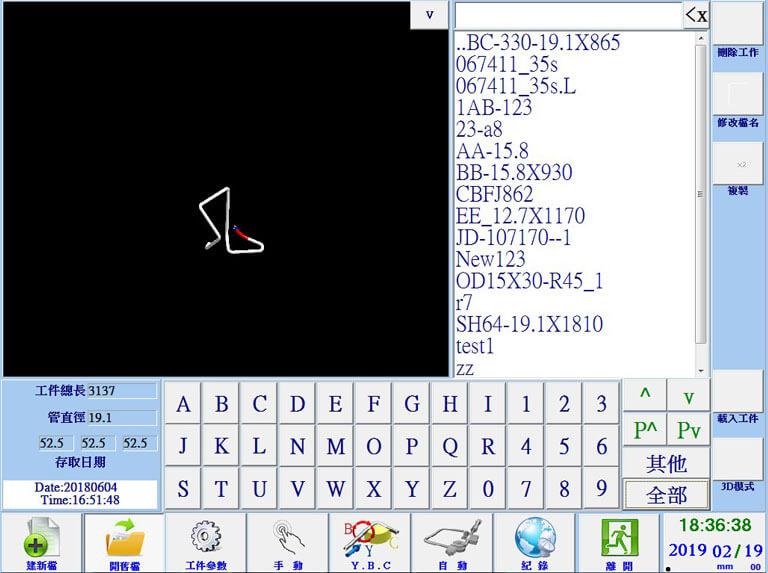

Open File Page