Please select your language

Language

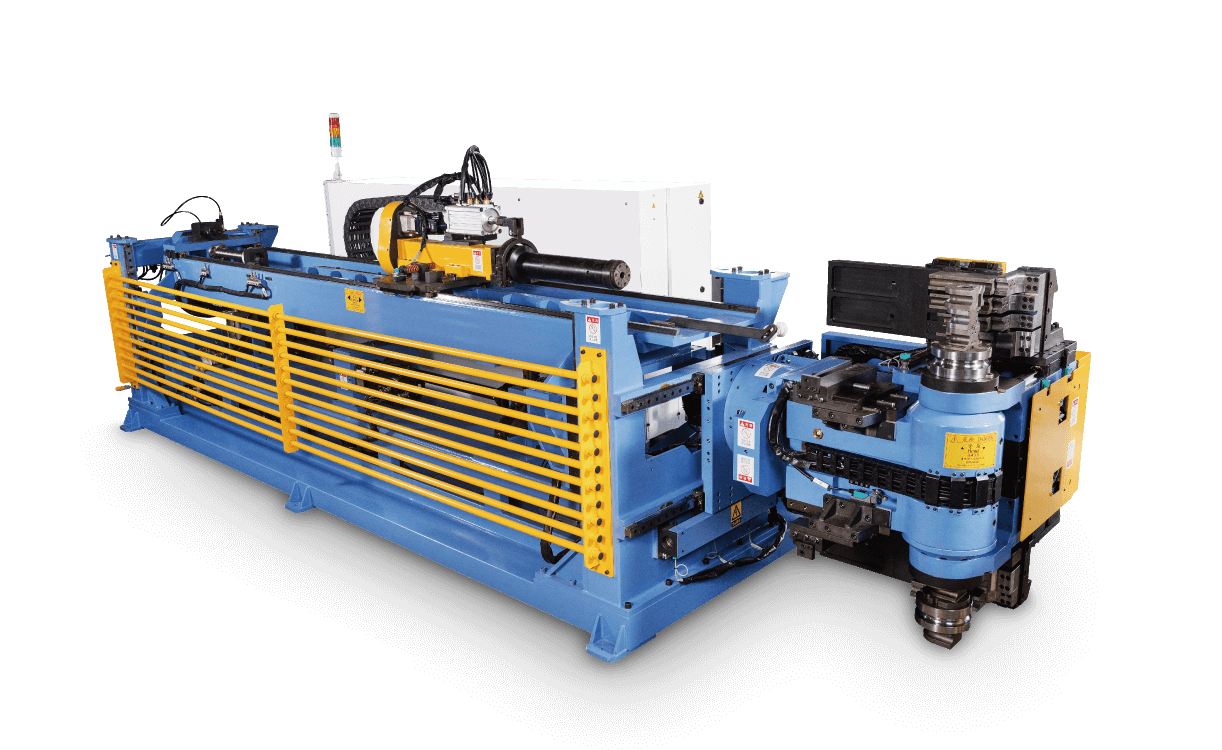

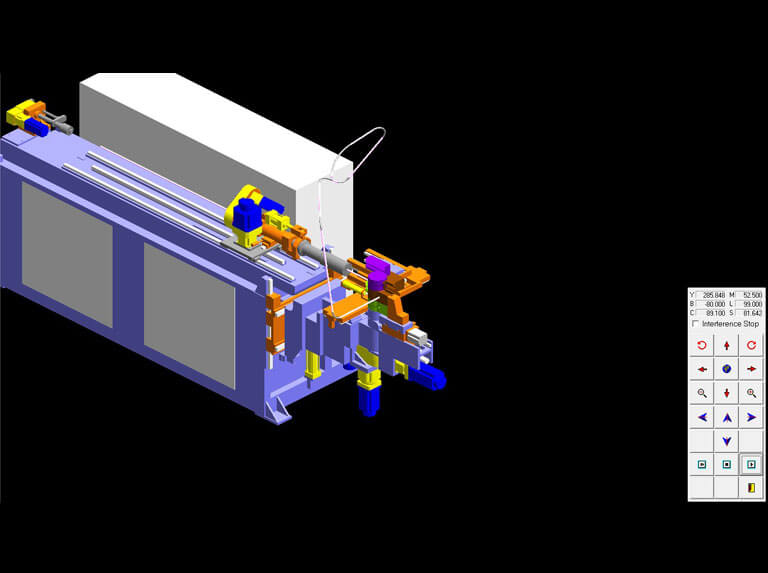

All Electric-Servo Control(11 Axes)

High programmable bending sequence can be driven through all-electric with 11 axes.

Low Noise

Low Pollution

High Accuracy

Abnormal Section Notification

Oil temperature effect free

Right-hand & Left-hand Bending in "One" process

Complex parts including right & left direction bending can be achieved during 1 process with highly precise performance.

Auto Tooling Positioning Function

Clamp/Pressure die are positioned automatically via smart control.

Safety Protection

- Fool-proof Function:

Improper operation notification to prevent the machine from the damage. - Comprehensive Safety Mechanisms:

Proximity sensors and Safety plates are set around the machine working zone to keep workers safe.

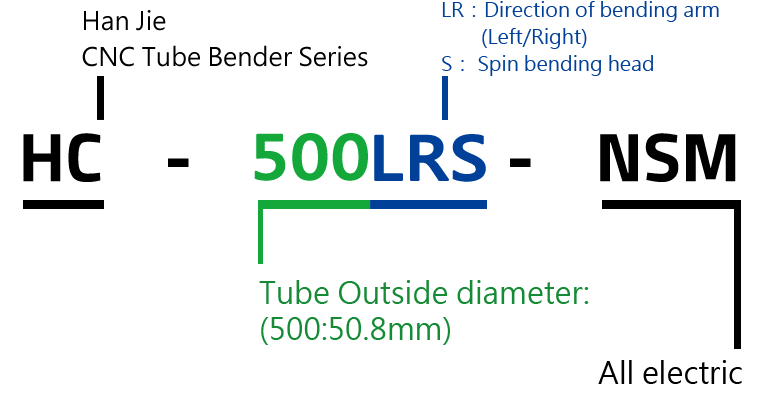

| Spec / Model | HC-500LRS-NSM | |

|---|---|---|

| Max. O.D. * W.T. | Mild Steel (mm) | Ø50.8 x 2.5T |

| Stainless Steel (mm) | Ø38 x 2.0T | |

| Square(Mild steel)(mm) | □38 x 2.0T | |

| Max. CLR | 200 mm | |

| Standard Mandrel Length | 2500 mm | |

| Max. Bending Angle Range | 190° | |

| Electric-Servo Speed | Feeding (mm/sec) | 1000 mm |

| Rotation (degree/sec) | 200° | |

| Bending (degree/sec) | 110° | |

| Electric-Servo Accuracy | Feeding (mm/sec) | ±0.05 mm |

| Rotation (degree/sec) | ±0.05 ° | |

| Bending (degree) | ±0.05 ° | |

| Max. Radius Difference | 60 mm | |

| Total Power | 41.1 Kw | |

| Dimension | 5200 x 1600 x 1900 mm | |

| Weight | 5,000 kgs | |

PC-Based Control

- 3D tube profile can be shown immediately when editing YBC program to help users.

- Under Auto mod, 3D tube graphic indicates current bending section by different color block.

- 3D Bending Process Simulation(Optional) directs bending process in advance to avoid unnecessary waste.

3D Bending Process Simulation (Optional)

3D Tube Simulation

sBend Software (HJ Development)

- Fast Workpiece Parameter Acquisition:

.dxf / .step files can be converted to Y.B.C data. - 3D Workpiece Preview:

Read-time 3D workpiece preview is acquired while Y.B.C data is programming. - 3D Bending Simulation:

Workpiece bending process can be previewed and verified in advance to prevent the waste.